Research and development is the key to keeping up with technological advances within the protective coatings industry. A&I Coatings technical department consists of a team of chemists who have a wealth of knowledge developed through their experience, education and study in this field. A&I Coatings was founded in 1981 by Graham Gillies, who originally worked as an industrial chemist for Balm Paints (now Dulux, Taubmans, and Industrial Metal Protectives (now Jotun). Some Grahams achievements include the introduction of polyurethane coatings to the Australian market, and some formulas developed by Graham still exist in Jotuns’ product range today.

According to the Asia-Pacific “Protective Coatings Industry Report- 2015”, the protective coatings market is growing at a CAGR (Compound Annual Growth Rate) of 10.22% from 2014 to 2019. With the ever growing market, new challenges and opportunities are presented to the A&I Coatings R&D for analysing, testing and developing.

According to the Asia-Pacific “Protective Coatings Industry Report- 2015”, the protective coatings market is growing at a CAGR (Compound Annual Growth Rate) of 10.22% from 2014 to 2019. With the ever growing market, new challenges and opportunities are presented to the A&I Coatings R&D for analysing, testing and developing.

A&I Coatings new developments with protective coatings include the addition of fire and smoke retardants, moisture and chemical repellents, weather and corrosion resistance, anti-bacterial coatings and the fluoropolymer technology. All this development is analysed and implemented in various coatings formulae,

and tested using hi-tech laboratory equipment.

Below are a few examples of the equipment that A&I Coatings have in their arsenal, and some example test results.

The Salt Spray Cabinet

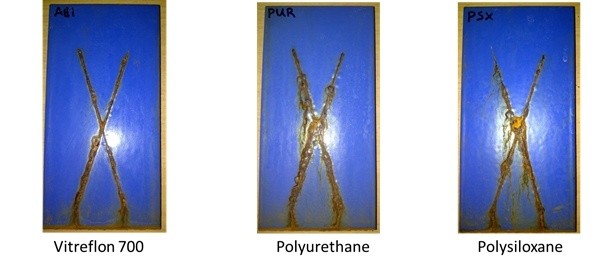

The Salt Spray Cabinet plays an important role with testing the corrosive performance of coatings by spraying highly concentrated salt water over coated metal samples with a large “X” score mark in the coating. The score mark has to be penetrated right through the coating system to the substrate, for the test to be effectively carried out.

The Salt Spray Cabinet plays an important role with testing the corrosive performance of coatings by spraying highly concentrated salt water over coated metal samples with a large “X” score mark in the coating. The score mark has to be penetrated right through the coating system to the substrate, for the test to be effectively carried out.

Over a period of time, rust creep will appear in the coating, indicating the coatings weather-ability and resistance against corrosion.

This test is performed in accordance with A.S 2331.3.1.

The photos below show three samples that have been exposed to 917 hours of spray within the salt spray cabinet.

The QUV Weatherometer

The QUV Weatherometer utilises high intensity Ultraviolet light to provide accelerated testing of a coatings performance when subjected to UV radiation, heat and humidity. UV light is the electromagnetic radiation with wavelengths varying from 10nm (very low) to 400 nm (extreme). The UV portion of sunlight ranges from 295nm to 400nm, as the lower wavelengths are eliminated by atmospheric absorption. Whilst the QUV Weatherometer simulates natural radiation as closely as possible, it is difficult to establish an exact correlation with real time weathering, so often comparative tests between coatings are conducted at the same time.

The A&I R&D Team test their coatings with UVB-313 lamps in a cycle of 8 hours UV radiation at 60˚C, followed by 4 hours condensation (high humidity) at 50˚C. They also, however, have the capability to use less harsh UVA-340 lamps and vary the test conditions.

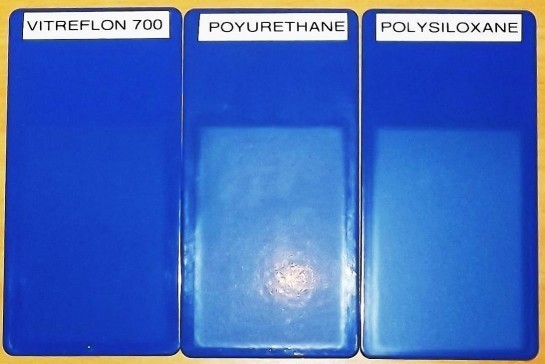

Due to the extremely harsh conditions of the test, the most useful results are gained by comparative testing. As demonstrated in the below test pieces, results are visible but also measurable by sheen/ gloss reduction and colour change (delta E).

Coating samples after 1976 hours exposure in the QUV Weatherometer.

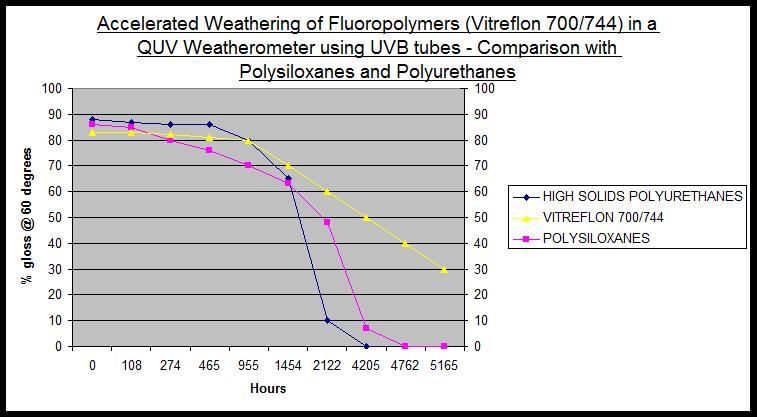

A typical QUV comparative test result displayed in a chart.

| Vitreflon 700 Fluoropolymer | Polyurethane | Polysiloxane | |

| Original Gloss @ 60 ̊ | 72.5 | 67.9 | 69.1 |

| Gloss after 2700 Hours Exposure | 44.1 | 2.2 | 1.9 |

| Gloss Retention as % | 61% | 3% | 3% |

| Colour Variation – dE | 5.87 | 18.71 | 11.64 |

Below is a graph displaying the accelerated weathering of a polyurethane, polysiloxane and fluoropolymer coating, using the QUV Weatherometer.

A&I Coatings operate all their QUV tests in accordance with ISO 11507, and to maintain accuracy and consistency, the QUV Weatherometer is calibrated regularly with a purpose built Radiometer which is in turn calibrated annually by the manufacturers.

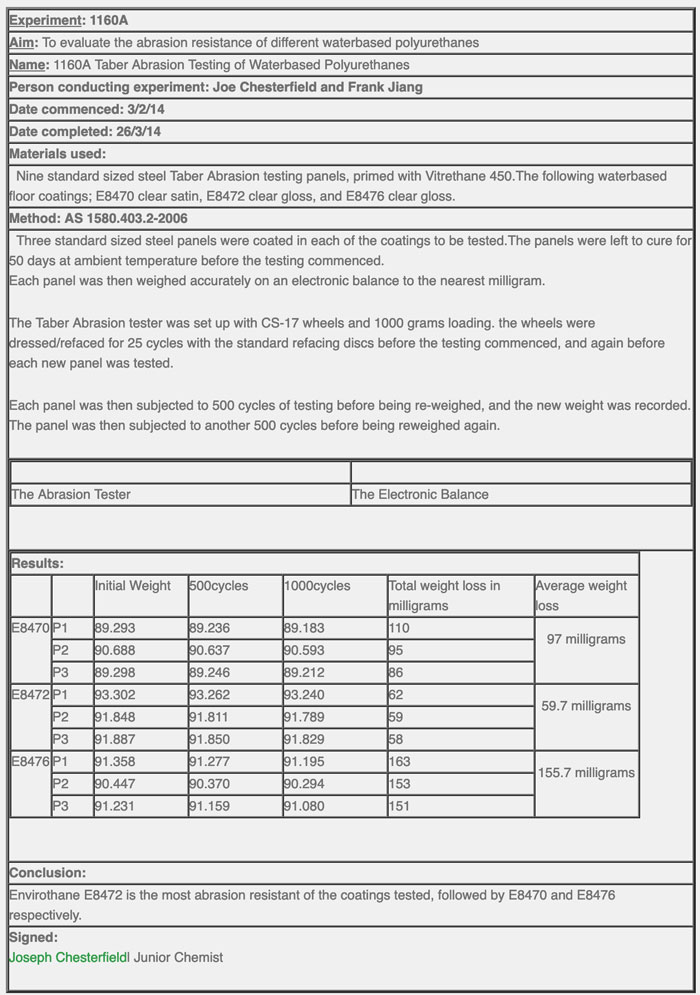

The Taber Abrasion tester

The Taber Abrasion tester provides standardised and repeatable abrasion resistance of coatings. Test data is expressed numerically (i.e as milligrams weight loss per 1000 cycles, making results very easy to incorporate into graphs and spread sheets.

Operated in accordance with AS 1580.403.2, this test is universally accepted as standard test practise and plays an exceptionally important role in the testing of coatings for the floor coating industry. As with most tests, the best results are gained by comparative testing. Variables from test to test include weight loadings, abrasive wheel hardness and frequency of refacing.

A typical Taber Abrasion test is displayed below:

These tests are just some of the experiments conducted within A&I Coatings laboratory, that lead to further product development. Other tests include:

- Chemical resistance

- Water immersion

- Coating elasticity and flexibility using plasticisers

- UV Cureable balsa wood coatings (with low resin uptake)

- Flame retardants

- Non-slip coatings (slip safety / slip resistance). See Non-slip Coatings ). This test is outsourced to CSIRO and/or authorised slip test contractors (ie: http://www.globalsafe.com.au ).

- Dust and gas proofing with membrane coatings

- Insulation

- Adhesion enhancement of coatings to various materials

The microscope is often utilised to examine the molecular structure of coatings in both liquid and inert form.

The Team at A&I Coatings are always looking forward in innovation and improvements in existing products and the development of new protective coating solutions. Contact us today if you think we can help with any projects!