A sealed grain silo is a crucial investment for farmers and wholesalers. Sealed silos ensure better grain insect control and the ability to fumigate. Fumigation is a safe and effective way to ensure the demise of weevils and grain destroying insects the presence of such extremely expensive.

A&I Coatings has supplied Grain Guards which seal grain silos since 2011.In this blog we discuss effective fumigation in sealed grain silos achieved with the aid of Grain Guards purchased from A&I Coatings.

How Are Insects Controlled In Grain Silos?

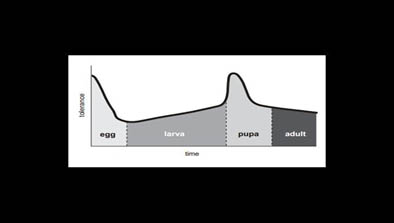

Grain insects go through four stages in their lifecycle: from egg to larva to pupa to adult. The phosphine gas needs to reach and be maintained at, a concentration possible only in a gas tight storage facility.

A sealed silo does save time during the fumigation process. Fumigation tablets should be place in trays in the headspace of the silo. The gas will circulate via air currents moving through the silo and control insects without needing to move the grain.

Figure 1 insect susceptibility to phosphine gas during life cycle stages

Fumigation Requirements In Sealed Silos

The concentration of phosphine required to successfully control all stages of insect development is 100ppm throughout the silo. This concentration must be maintained for at least seven days. Ten days is, in fact, recommended to allow the tablets to fully propel their gas followed by a ventilation period of three days. Wind blowing against a leaky silo is a common occurrence and the chimney effect of the pressure difference draws the gas out of the silo, leaving some eggs and pupae behind.

A temperature of above 25 degrees celsius requires an exposure period of seven days, however a climate of 15-25 degrees celsius requires a full ten-day cycle to be effective. Under no circumstances fumigate when grain temperatures are below 15 degrees celsius or when grain moisture content is below 9%.

A dose rate of two tablets per tonne of silo capacity is recommended.

Fumigation In Unsealed Environments

Furthermore, it must be noted that effective fumigation is impossible to achieve in an unsealed silo. Do not fumigate in a silo that is not sealed. Fumigating in an unsealed silo or field bin constitutes an off-label use and results in ineffective fumigation and the development of an exceptionally phosphane-resistant insect population. In unsealed storage areas we recommend the use of diatomaceous dust.

Why Does A&I Coatings Sell Grain Guards?

A&I Coatings Acquired the Dominion Plastics Business in 2011. Dominion Plastics had been involved in membrane coatings for sealing grain silos for many years, and also designed in collaboration with authorities the Grain Guard pressure safety relief valve as a simple but effective attachment for maintaining the correct air pressure within the silo, at the same time preventing insects from accessing grain stored in the silo. Grain guards are also known as silo relief valves, oil bath valves or breather boxes. Contact helpdesk@aicoatings.com for more information, or orders@aicoatings.com to order units.

The following Guide published by Grains Research and Development Corporation helps…