See here Vitrethane 182N

A glass primer is an adhesion promoter for the non-porous surface of glass to ensure the print or topcoat bonds to the surface effectively.

Glass is a versatile, multifunctional product and is an integral material in our daily lives and in the construction industry. The many applications of glass to different aspects of the industry necessitate different processes before they reach their end use.

Do you need Primer to paint Glass?

Glass used in interiors, both commercial and residential can be used along with a print or paint found on the splashback of a kitchen. Due to the non-porous nature of the glass, it is hard to achieve adhesion, hence the need for a primer. A primer as an adhesion promoter is crucial to ensuring your top coat bonds sufficiently to the glass surface.

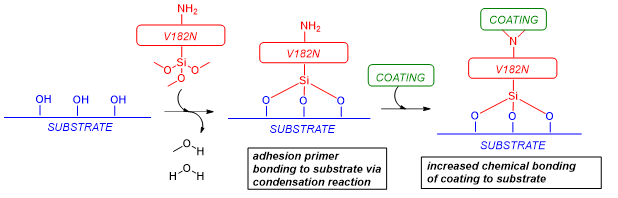

A & I Coatings VITRETHANE 182N is a ready to use, clear, low viscosity primer containing reactive coupling agents which function as an adhesive for glass and other substrates. It bonds to the substrate via a hydrolysis reaction with moisture from the air. It acts fast and has good flow properties making it easy to use. Specialist equipment isn’t necessary for application.

The primer is silane-based and specifically formulated for all glass substrates making it perfect for glass splashbacks and windows. It is also suitable for use on substrates including aluminium, ceramic tiles and brass. Chemically, it acts to replace hydroxyl functionality on the substrate with amino and organic properties which increases the chemical bonds to the coating.

How to Apply

Applying V182 using spray, dip, or polyester felt applicator is possible due to its versatility. The ideal application procedure comprises of first cleaning the glass substrate thoroughly and then stirring the primer until homogenous. The next step involves applying a Wet Film Thickness of approximately 30 microns to the substrate and then allowing to hydrolyse in moist air (50 – 80% RH) between 21ºC and 35ºC) for a minimum of one hour in which the coating will cure and form a dry film thickness of approximately 2 microns. The hydrolysis time reduces through heating.

The Vitrethane 182N is then ready to topcoat or print.