Click below for answers to your product questions:

Enviroflon 8480 hardener must be power stirred into the base to ensure thorough blending of the part A & B. Many solvent based products can be hand stirred or stirred with a slow RPM drill, neither of which methods are suitable for mixing E8480.

The key is to use a stirrer which will spin at a fast enough RPM to blend the part A & B correctly without causing the paint to splash out of the top of the bucket. A battery or electrical drill is sufficient.

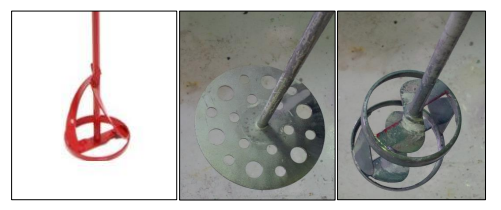

Photos of stirrers which can typically achieve this are below.

For larger volumes:

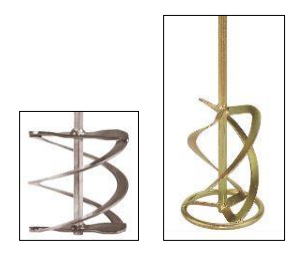

For smaller volumes a stirrer along the lines of the below image must be used so that the RPM can be achieved without the paint splashing out of the drum.

Photos of stirrers which won’t achieve the desired outcome are below. These stirrers won’t be able to achieve the RPM needed without splashing the paint out of the bucket.

When the base and hardener are mixed together initially the mix will be a lumpy consistency. As you continue to stir the mix it will become smooth (approx. 3 minutes) at this point water can be added to achieve the correct viscosity for brushing, rolling or spraying. The mix needs to be power stirred again after the water is added. The water must not be added before the base and hardener has been thoroughly mixed.

For the ultimate success of the E8480, application in direct accordance with the technical data sheet is crucial. E8480 must be applied at a consistent wet film thickness of 125 microns, to achieve the correct dry film thickness of 50 microns. Delamination can occur if the correct DFT is not achieved.

When applying the E8480 over epoxy undercoats, it is very important for the E8480 to be applied at the recommended film thickness. Failure of the product can occur if the product is applied too thinly.