The fluoropolymer systems used by A&I coatings are advantageous to many other PFAS fluoropolymers

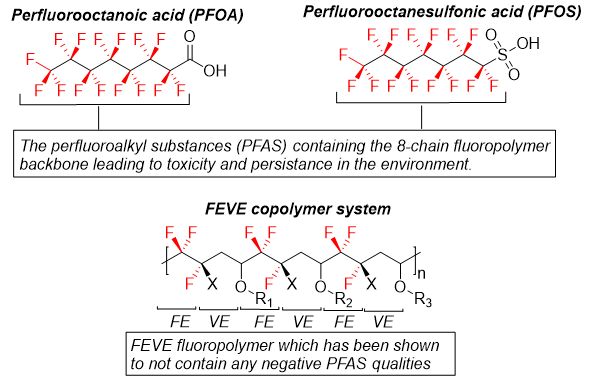

due to their unique fluoroethylene vinyl ether (FEVE) structure. They do not degrade into polyfluoralkyl substances such as the acids Perfluorooctanoic acid (PFOA) and Perfluorooctanesulfonic acid (PFOS), which are resistant to normal environmental degradation processes. These types of PFAS were defined by the Organisation for Economic Co-operation and Development (OECD) in 2018 as “fluorinated substances that contain at least one aliphatic carbon atom that is both saturated and fully fluorinated (without any H/Cl/Br/I atom attached to it), i.e. any chemical with at least a perfluorinated methyl group (–CF3) or a perfluorinated methylene group (–CF2–) in its structure”.1 Due to the FEVE polymer structure containing both a halide atom (Cl/Br/I) and a methylene unit (-CH2-) (fig 1).

Fig 1: The PFAS substances PFOA and PFOS have high persistence in the environment due the chemically inert perfluorinated 8-chain backbone.

The FEVE systems have been thoroughly tested and found to contain PFAS substances below 5 parts per billion, meeting the regulation limit of <10mg/kg for PFOS and <1mg/kg for PFOA. Due to this testing, FEVE fluoropolymers have been approved for use by AICS (Australian Inventory of chemical substances) and comply with the UK’s Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations and meet all health regulations regarding environmentally persistent fluoroalkyl compounds.2

High molecular weight fluoropolymers such as FEVE systems possess a unique combination of properties and unmatched functional performance critical to the products and manufacturing processes they enable and are irreplaceable in many uses. Studies also demonstrate that FEVE fluoropolymers are a distinct and different group of PFAS and should not be grouped with other PFAS for hazard assessment or regulatory purposes.3

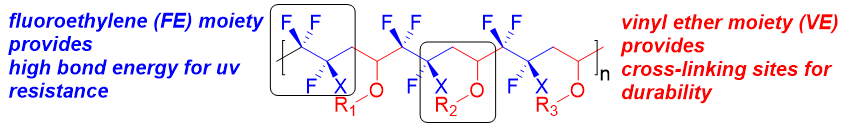

A&I Coatings’ fluoropolymer systems have been used extensively for many years to provide uv durable coatings for industrial and steel applications. These coating systems not only provide excellent uv resistance, but in-built chemical and graffiti resistance. The unique properties are the result of the fluoropolymer resin used, the solvent soluble FEVE copolymer (fig 2). Unlike any other fluoropolymer resins, the chemical composition of the FEVE is an alternative copolymer of vinyl ether (VE) and fluoroethylene (FE) monomers.

Fig 2: chemical structure of the FEVE fluoropolymer which is composed of alternating fluoroethylene (FE) and vinyl ether (VE) moieties.

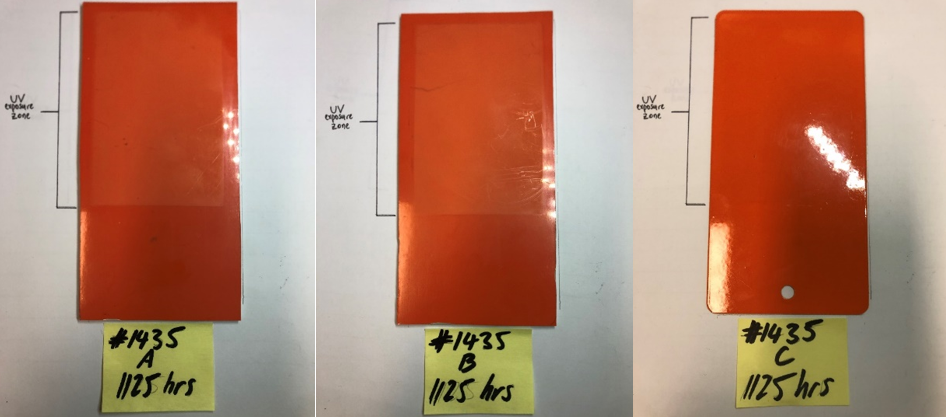

The vinyl ether (VE) monomer provides the resin with multiple sites for cross-linking, creating a tough coating with high durability and excellent chemical resistance. The fluoroethylene monomer (FE) provides the copolymer chain with high bond energy, which has been shown to limit the degradation of uv energy when compared to other resins with lower bond energy such as polyurethane. These FEVE resins have undergone extensive laboratory testing and shown superior uv resistance when compared to other common coating systems designed for outdoor longevity (table 1).

| entry | topcoat | QUV exposure (hours) | gloss (uv shielded zone) | gloss (uv exposure zone) | gloss variation |

| A | Competitor system | 1125 | 64.7 | 8.4 | -87.6% |

| B | Competitor system | 1125 | 63.4 | 7.9 | -87.5% |

| C | A&I FEVE fluoropolymer | 1125 | 89.5 | 83.9 | -6.3% |